是否需要更换滚珠丝杠螺母以便旋转? 这个设计的滚珠丝杠模组有什么特点和优势?,10. KURODA滚珠丝杠的售后服务如何?,3. 他们的升降台产品有哪些主要的技术特点? ,8. 促销的滚珠丝杠是否适用于哪些行业或领域?,3. 什么是铁灰?,5. 肇庆滚珠丝杠加工的产品有哪些应用场景? ,5. 滚珠丝杠屈曲载荷计算公式的推导过程是怎样的?,7. 滚珠丝杠副传动的应用领域有哪些?,6. 该厂是否提供定制服务?,10. 有哪些常见的问题需要注意?

来源: | 发布时间:2023-06-24 09:13:16

滚珠丝杠螺母转不动可能有以下几个原因:

1. 滚珠丝杠螺杆损坏或严重磨损,导致滚珠无法正常滚动。

2. 滚珠丝杠螺母内部损坏或磨损,导致与滚珠丝杠配合不良。

3. 滚珠丝杠螺母紧固力过大,导致摩擦力增大,难以转动。

4. 滚珠丝杠螺母表面沾染杂物、灰尘等物质,影响滚珠滚动。

解决方法:

1. 更换滚珠丝杠或螺母。

2. 清洗滚珠丝杠和螺母,确保表面干净。

3. 调整滚珠丝杠螺母的紧固力,避免过紧。

4. 油润滚珠丝杠和螺母,确保滚珠正常滚

相关问题:

滚珠丝杠和梯形螺纹的精度有什么不同?

Ball Screw: A Review Introduction: Ball screws are mechanical devices used to convert rotational motion into linear motion and vice versa. They are used in a wide range of applications, including machine tools, robots, aircraft, and automotive systems. Ball screws offer many advantages over other types of screws, such as high efficiency, high precision, and low wear. This paper provides a brief overview of ball screws, their construction, working principles, and applications. Construction: A ball screw consists of a screw shaft, a nut, and a set of balls. The screw shaft has a thread profile that matches the profile on the inside of the nut. The balls are located between the screw shaft and the nut, and they roll along the thread profile as the screw shaft rotates. The rolling action of the balls reduces friction and wear, making the ball screw more efficient and durable than other types of screws. Working Principles: Ball screws work on the principle of recirculating balls. As the screw shaft rotates, the balls roll along the thread profile and are carried by the nut. The balls are then forced back to the starting point by a return tube located in the nut. This recirculating action allows the ball screw to achieve high efficiency and precision. Applications: Ball screws are widely used in applications that require high precision and efficiency, such as machine tools, robots, and aerospace systems. They are also used in automotive systems, such as power steering and suspension systems. Ball screws are preferred over other types of screws in these applications because of their high accuracy, low wear, and high efficiency. Conclusion: Ball screws are mechanical devices used to convert rotational motion into linear motion and vice versa. They offer many advantages over other types of screws, such as high efficiency, high precision, and low wear. Ball screws are widely used in applications that require high precision and efficiency, such as machine tools, robots, and aerospace systems. They are also used in automotive systems, such as power steering and suspension systems.滚珠丝杠和梯形螺纹的价格是否相同?

不完全一样。滚珠丝杠和梯形螺纹都是用于将旋转运动转化为线性运动的机械元件,但它们的结构和工作原理略有不同。 梯形螺纹是一种三角形断面的螺旋形结构,它的螺距是固定的,转动时螺纹峰和螺纹谷会相互插入,从而将旋转运动转化为线性运动。 而滚珠丝杠则是在螺纹表面镶嵌了一些小球,这些小球可以在滚动过程中将运动力传递给丝杠。相对于梯形螺纹,滚珠丝杠的性能更加优良,可以实现更高的转速和负载能力。 因此,虽然它们都是将旋转运动转化为线性运动的机械元件,但滚珠丝杠和梯形螺纹在结构和性能上存在较大差异。

3. 高刚性:多头滚珠丝杠的结构紧凑,具有很高的刚性,可以承受大的负载和惯性力,

7. 绘制滚珠丝杠的球形滚珠,并在其周围绘制一个圆形,作为滚珠丝杠的内径,

7. 工作温度范围:通常在-30℃至+100℃之间,

4. 检查滚珠丝杠的润滑情况,是否需要添加润滑油或脂,滚珠丝杠带预压是指在滚珠丝杠的安装过程中,通过对滚珠丝杠支撑轴承的预压来保证滚珠丝杠的运行稳定性和精度,

6. 文字:标注相关信息,

2. 高效率:由于滚珠丝杠的滚珠可以减小摩擦力,因此滚珠丝杠比普通螺纹丝杠更容易实现高速运动,滚珠丝杠水平安装方式一般有以下几种:

1. 水平安装:滚珠丝杠与工作台平行安装,滚珠丝杠的轴线与工作台的移动方向垂直,

2. 调整滚珠丝杠的预紧力:适当调整滚珠丝杠的预紧力可以减少回弹的程度, 该试验通常用于评估机械零件、汽车零件、工业设备和其他应用中的材料

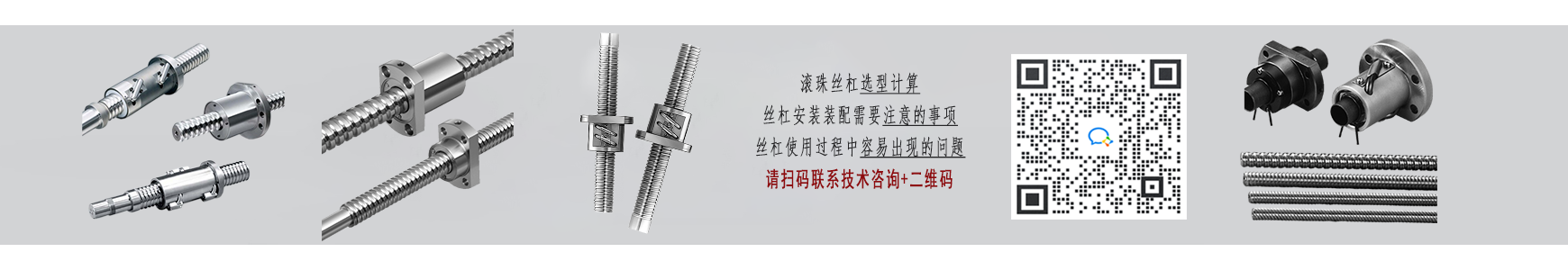

请扫码获取更多信息

推荐阅读

云南滚珠丝杠每转多少度可以达到一定的位移?

2023-06-24

NS滚珠丝杠的成本是怎样的?

2023-06-24

这种仪器在国内外市场上的销售情况如何?

2023-06-24

它的维修保养方法是什么?

2023-06-24

滚珠丝杠传动的应用范围是什么?

2023-06-24

有哪些注意事项需要在使用滚珠丝杠刀具时需要遵守?

2023-06-24

这个滚珠丝杠螺母可以承受多大的负载?

2023-06-24

这些规格的精度如何?

2023-06-15

滚珠丝杠轴承的工作原理是什么?

2023-06-09

该电机的寿命有多长?如何延长其使用寿命?

2023-06-06

下一个:8. 该厂家的产品价格是否合理?